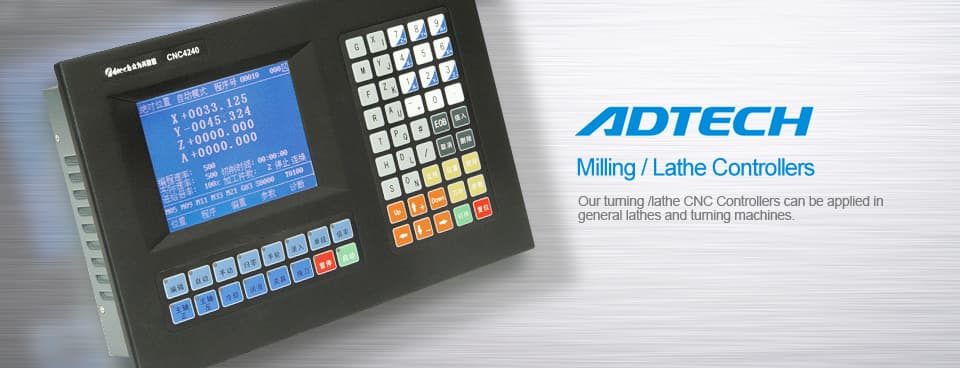

Model: ADT Series / High-Precision CNC Control System

The ADTECH CNC Controller Series provides high-speed, high-accuracy motion control solutions for industrial machining applications. With integrated motion, I/O, and communication modules, the ADTECH controller ensures smooth interpolation and stable operation for complex multi-axis systems.

Designed with a user-friendly HMI and G-code compatibility, the ADTECH CNC platform simplifies configuration and enhances productivity for machine tools such as lathes, milling machines, and engraving systems. It combines precision, flexibility, and reliability in a compact industrial-grade unit.